HARD SURFACE FLOORING & ACOUSTIC RATINGS: THE REAL STORY

Virtually all human activity produces noise of some kind, and life in general seems to get noisier all the time. Noise is even recognized as a form of pollution, a detrimental influence to be managed and minimized.

In recent decades, noise has become a big issue in the building industry. As more and more of us live in multi-family towers and work in high-rise office towers, we’re increasingly surrounded by ever more sources of noise, much of it human-generated. Architects and builders try to design buildings that reduce interior noise. They use materials and methods specially designed to minimize sound transmission between walls and between floors.

Naturally, professionals need to be able to measure a material’s capacity to reduce noise, so they can make informed choices about which materials to specify on a given project. They do that by referring to sound ratings, based on universally recognized ASTM tests. Which sounds straightforward, but in practice, it’s not. With this short overview, we’ll try to demystify the acoustics ratings process, and show you how to assess the accuracy of ratings information.

SOUND DISTINCTIONS

Interior sounds are classed into two groups:

1. Sound Transmission Class (STC) refers to air-borne sounds such as voices, TV or music. These are the sounds you would hear through the walls, floors and ceilings you share with your neighbor.

2. Impact Insulation Class (IIC) are structure-borne sounds, sounds generated by something impacting the actual building structure—like footsteps on a hard floor, which you would hear in the room below. In our business, this is the class we’re most interested in.

Delta IIC is most valuable for comparing the real acoustic benefit of different flooring options. It measures the added impact sound isolation provided by just the flooring and underlayment combination. This makes it particularly useful for isolating the performance of different underlayment's under the same flooring.

RATINGS EXPLAINED

The rating most commonly used to evaluate acoustic properties in the building industry is IIC. IIC ratings are obtained through a testing procedure specified by the American Society for Testing and Materials (ASTM) an independent US-based organization that creates testing protocols for the construction industry and many other fields. Materials manufacturers and building professionals use these standards as a reliable, third-party method to gauge product performance. There are a number of ASTM tests related to measuring IIC sounds.

ASTM E492 IIC Lab Test: This is performed in a controlled, laboratory setting. However, the parameters of the testing scenario can vary greatly, as we’ll describe below.

ASTM E1007 AIIC Field Test: An IIC test that is performed in an actual building location rather than a lab. This rating was formerly labeled FIIC. Because every building is different, AIIC ratings make a poor general guide to a specific material’s acoustic properties but are useful in comparing multiple different systems in the actual environment in which they will be used.

ASTM E2179 Delta Test: A Delta rating pertains to a very specific lab test scenario using a 6” thick slab substrate with no ceiling assembly below. The Delta IIC is the most transparent rating and for that reason is most preferred by industry professionals.

There are some other ratings variations used as well.

NISR (Normalized Impact Sound Rating): A field test that is adjusted to represent a lab-type result and nullify any field discrepancies.

HIIC (High IIC): A variant on the IIC test that filters out sounds below 400hz – the ‘thump and thud’ or ‘bass’ range. Current acoustic technologies have little or no measurable effect on these sounds, so the HIIC focuses on the range of sound that acoustic materials seek to control.

Difference: This is not a technical rating but is commonly used to describe the acoustic performance of a single flooring component or assembly. In our example above the flooring and underlay boosted the IIC rating from 34 to 57, so we can say this flooring &underlay combination has a difference rating of 23.

THE TESTING PROCESS

The drawback to relying exclusively on an ASTM IIC lab test is that it does not dictate the make-up of the overall floor-ceiling assembly being tested because the test must be flexible enough to test all different types of building materials.

This leads some manufacturers to fabricate a high-performance flooring assembly that is designed to maximize the rating their product achieves but would likely never be used in a real building. In our example above, the use of a high-performance assembly boosts the IIC rating from a reasonable 57 to a completely unrealistic 72, for the same flooring and underlay combination!

What is driving this trend? Essentially it is a questionable marketing practice (think "Your Mileage May Vary") which has become adopted in consumers’ minds as the ‘industry standard’.

As hard surface flooring becomes more popular, property managers and condo strata councils are imposing strict guidelines on what types of flooring may be installed in their buildings. Based largely on the inflated claims of flooring and underlay manufacturers, they insist on products that meet a threshold of IIC 72 (or higher). Condo boards set an unreasonable specification, manufacturers game the testing regime to meet it, and consumers end up buying floors based on unrealistic expectations.

As a consumer, when you see a floor or underlay with a rating of IIC 72 or more, you can usually assume two things:

-

The rating was very likely obtained using a high-performance assembly designed for the purpose of achieving a high IIC number, as shown in the example above.

-

The product will never perform to that level when installed in a typical condo or townhouse. Without the use of a high-performance assembly, the only floorcovering likely to achieve a legitimate IIC 72 is wall-to-wall carpeting with an underpad.

But as an informed consumer, you can look past the rating and make a more realistic assessment of the product’s likely performance.

Our advice? Choose a style of flooring that meets your taste and lifestyle. Acoustically, most floors of similar quality and construction will perform pretty much the same.

If you’re looking at a product with a published IIC rating, ask how it was obtained, which ASTM tests were used, and what the actual flooring assembly consisted of. The answers may surprise you.

If sound control is an issue, ask your flooring dealer about acoustic underlays. These can do a lot to reduce flooring noise, making life more comfortable for you as well as your neighbors.

Use area rugs or runners in high-traffic areas to help minimize noise. And make it a habit to wear soft-soled slippers or footwear when indoors. Again, it will not only make life quieter for the neighbors but may help save some wear and tear on your new floor as well.

OUR HOUSE STANDARD

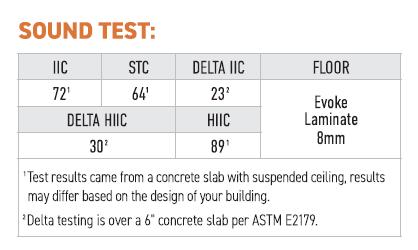

Metro’s standard acoustical testing and recommendations focus on the ASTM Delta IIC as the best potential for comparing different flooring systems and their true acoustical value. This rating is also the one used most commonly in the industry.

We often also perform a standard IIC test over a ‘high-performance’ ceiling assembly consisting of a concrete slab with a suspended ceiling and gypsum board. This test may have relevance to consumers whose building has the same or similar design, but it will also deliver the optimized IIC rating that is commonly used to evaluate products.

The test results will also indicate what materials are being tested. In some cases, it will be a flooring material alone, and in some cases, an underlay will be added. Testing of several products in different combinations allows comparative assessments between different flooring types and underlay options.

Image: Example of IIC ratings as shown on an acoustic underlay product sheet.

1. Marketing number.

2. The ASTM E2179 professional number based on third-party standards (the ASTM sited above).